USB Camera modules have been used in various different devices in our life. With the development of technology, the camera module is not untouchable in civil usage, even customized OEM Camera module is available in many manufacturers. Today we will go through the basic knowledge of the USB camera module manufacturing process.

The manufacturing process of USB Camera Module• Current test

Connect the computer, ammeter, and module with the test cable to check whether the standby current and working current of the module is within the normal range. After opening the image and check whether the screen is normal. If there is an LED light, check whether it lights up after opening the image.

• Photosensitive component cleaning

Use 40 times “computer microscope” to check, and use a dust-free wiping cloth with a little alcohol to clean the Sensor surface. After confirming that the sensor surface is free of dirt, oil, lint, or scratches, install the cleaned lens.

• Lens focusing

In the lightbox, place the Module in the fixed fixture and aim at a certain distance of the focus chart (Chart), and start the software IQC Focus to watch the image.

Align the center of the image with the center of the sun chart and adjust the focus. At the same time, according to the black and white card, check whether the image is bad. The brightness of the light source at the center of the focus chart is between 450 Lux and 550 Lux.

• Lens dispensing

Use the dispensing bottle to place a small drop of screw on the left and right sides of the joint between Lens and Holder and the four sides of the joint between Holder and PCB. After the glue is dispensed, send the module to the drying room for 3 hours and wait for the screw fixing glue to completely solidify before proceeding to the next step.

• Copper foil

Remove the copper foil and paste it on the back of the PCB. Fold the copper foil with Mylar on the front of the PCB and fold the copper foil on the other side.

• Appearance inspection control

Full function & FQC appearance inspection

Product length, width, and height inspection.

Visually check that there are no foreign objects or glue in the PCB board positioning holes.

Visually verify that the position of the LABEL sticker is correct. The model number on the LABEL sticker must be the same as the model number. The LABEL sticker must not be smeared, worn, and warped, or skewed.

Do not stick, skew or lift the adhesive on the eye

There should be no foreign objects or scratches on the surface of the lens

Functional inspection and control focus

Full function & FQC inspection

Place the Module in the fixed fixture and aim at the sun chart at a certain distance, start the software on the PC to watch the image, check whether the focal length is adjusted, check whether the image is normal according to the black and white card. The brightness of the light source at the center of the sun image is between 680 Lux and 780 Lux.

Use test fixtures and software to perform recording test judgment on the finished module, and use headphones to listen to the recording to detect whether the recording is sound and whether there is noise.

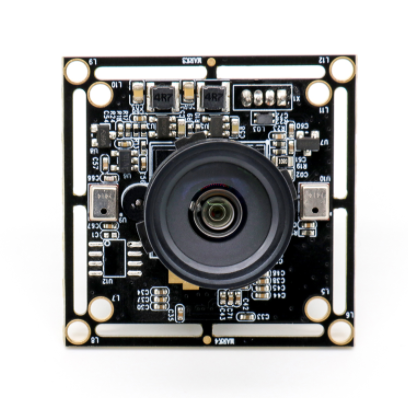

Hampo 16MP USB Camera Module

003-1170 is an ultra high resolution with a real 4K 16MP USB camera module, adopting a large size 1/2.8” CMOS Sony IMX298 sensor, the max resolution4720*3600 @30fps. Compatible with Windows XP(SP2, SP3)/Vista/7/8/10, Linux or OS with UVC driver.

Features:

• 16MP Ultra HD Resolution: 4K USB camera module ultra HD webcam module. Max resolution:4720*3600@30fps. Wide use for high levels video systems of education or administration like document scanning, smart blackboard, beauty equipment, etc. MJPG/YUV compression format optional, fast transmission, recorded clear, vivid, and colorful video. Support OTG optional.

• High-Quality Sony Sensor: The camera adopts a 1/2.8” high-quality CMOS Sony IMX298 sensor. The camera could make all the corner of files looks as clear as the center part, not blurred during document scanning.

• Quick Plug&Play: This USB camera is easy to use, only plugs the camera into a computer USB port, and running the software can make video display and recording work. No driver installation is required.

Dongguan Hampo Electronic Technology Co., Ltd, is a professional manufacture of all kinds of audio and video electronic products company, having our own factory and R&D team. Support OEM&ODM service. If our off-the-shelf products almost meet your expectations and you just need them to be better tailored to your needs, you can contact us for customization just by filling out a form with your requirements. In addition to USB camera modules, we also supply MIPI camera modules, DVP camera modules, and PC cameras. OID devices such as talking pen and smartpen. If you are interested in our products, please feel free to contact us!

Post time: Nov-20-2022