What is a sensor?

A sensor is a device that detects and responds to some type of input from the physical environment. The input can be light, heat, motion, moisture, pressure or any number of other environmental phenomena. The output is generally a signal that is converted to a human-readable display at the sensor location or transmitted electronically over a network for reading or further processing.

Sensors play a pivotal role in the internet of things (IoT). They make it possible to create an ecosystem for collecting and processing data about a specific environment so it can be monitored, managed and controlled more easily and efficiently. IoT sensors are used in homes, out in the field, in automobiles, on airplanes, in industrial settings and in other environments. Sensors bridge the gap between the physical world and logical world, acting as the eyes and ears for a computing infrastructure that analyzes and acts upon the data collected from the sensors.

How to Bringup a Sensor?

1. Background

Generally, when we debug the effect of a sensor, we first need to light it up, which is also called sensor bringup. This part of the work is mostly done by the driver engineer, but sometimes it also needs to be done by the tuning engineer.

But in fact, if it goes well, after configuring the sensor setting, i2c address, and sensor chip_id in the sensor driver, the picture can be produced, but in most cases, it is often not so smooth, and many problems will be encountered.

2. Sensor bringup process

Apply to the sensor factory for the required specifications of the Sensor setting, including resolution, Mclk, frame rate, bit width of the output raw image, and the number of mipi_lanes. If necessary, explain that the maximum mipi rate supported by the platform cannot be exceeded;

After getting the setting, configure the sensor driver, first configure the sensor setting, I2C address, chip_id;

Get the schematic diagram of the motherboard, confirm the hardware related configuration, and configure the pin control of mclk, reset, pwrdn, i2c in dts according to the schematic diagram of the motherboard;

After the above steps are completed, if there is no problem with the hardware, you can basically light up the picture, and then configure the sensor’s exposure time, analog gain and other registers in detail according to the sensor datasheet;

3. Problem summary

a. How to determine the pins of reset, pwrdn, i2c, mclk?

First of all, you have to learn to read the schematic diagram. I was very confused when I got the diagram at the beginning. I felt that there were too many things in a mess. I didn’t know where to start. In fact, there are not many places to pay attention to. I don’t need to understand the whole diagram.

Because we mainly configure the camera, find the MIPI_CSI interface part, as shown in Figure a, and only focus on the control pins of CM_RST_L (reset), CM_PWRDN (pwrdn), CM_I2C_SCL (i2c_clk), CM_I2C_SDA ( i2c_data ), and CM_MCLK (mclk) up

b. I2C fails?

The i2c address is wrongly configured: Generally, i2c has two addresses, and the level is different when it is pulled up or down.

Check the problem of hardware power supply AVDD, DVDD, IOVDD, the three power supplies of some hardware are constant power supply, and some three power supplies are controlled by software. If it is controlled by software, you need to add these three power supplies to the driver control pin.

The configuration of the mclk pin is wrong: you can use an oscilloscope to measure whether the clock provided to the sensor is available, or whether the clock is correct, such as: 24MHz, 27MHz.

Incorrect i2c pin configuration: Generally, you can check the corresponding pinmux-pins file of the main control to confirm whether the corresponding GPIO has been defined correctly;

c. No image or abnormal in image;

Enter the command on the ISP side to check whether there is err in the transmission of mipi.

The mipi signal can be measured with an oscilloscope.

Grab the raw picture to see if there is any abnormality. If there is an abnormality in the raw picture, it is generally a problem with the sensor setting. Ask someone from the original sensor factory to check it.

After increasing the gain, there are vertical stripes (also called FPN), which are related to the sensor, and generally find the original sensor factory to deal with;

What kinds of sensors are included in Hampo camera?

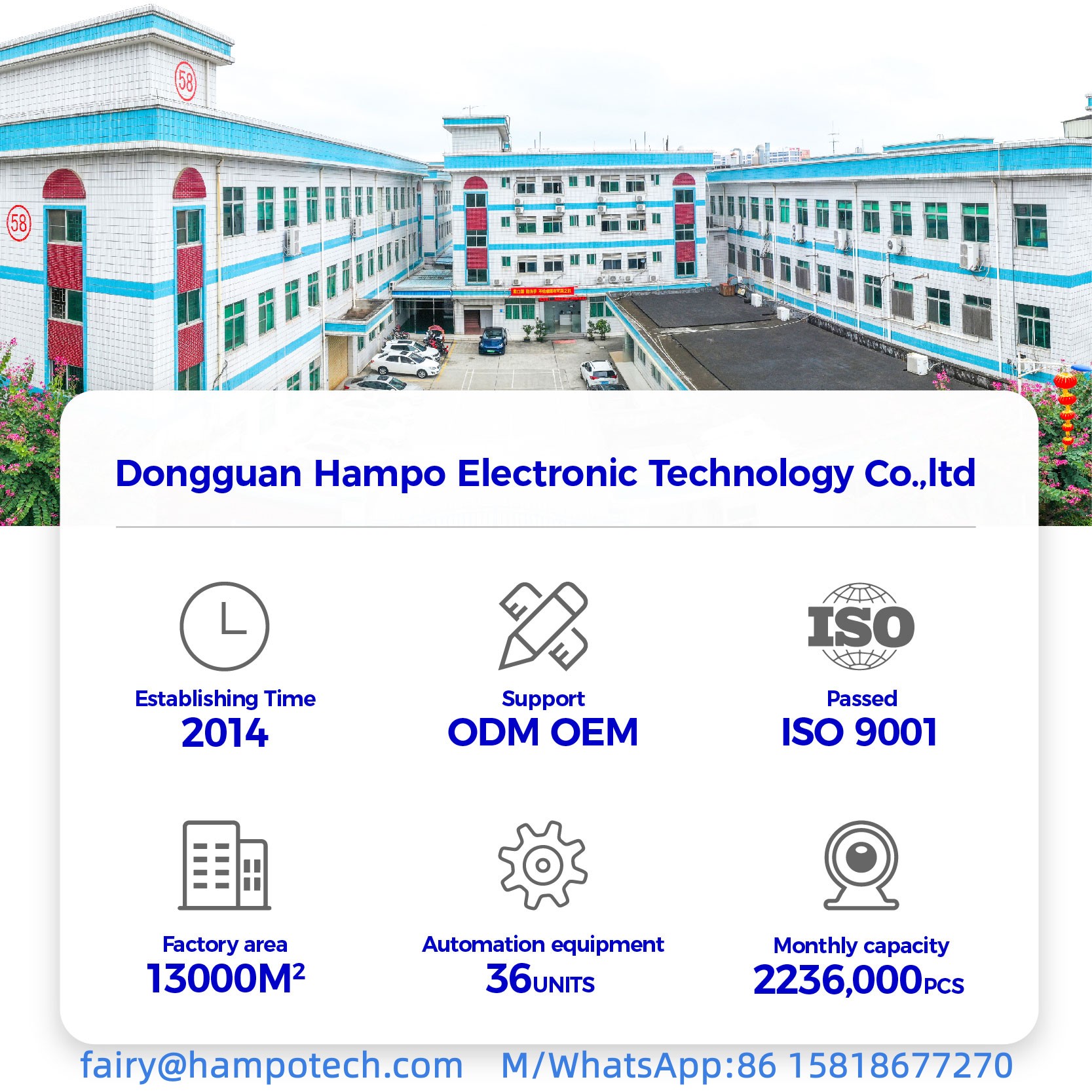

Dongguan Hampo Electronic Technology Co., Ltd, which was founded in 2014, is a manufacturer specialized in design, R&D and manufacture of audio and video electronic products, who has more than 10 years of experience on this industrial.

In order to meet the customization needs of customers, Hampo is constantly enriching its products, during which many sensors have been light up, mainly including the Sony series: IMX179, IMX307, IMX335, IMX568, IMX415, IMX166, IMX298, IMX291, IMX323 and IMX214 and so on; Omnivision series like OV2710, OV5648, OV2718, OV9734 and OV9281 etc.; Aptina series like AR0230, AR0234, AR0330, AR0331, AR0130 and MI5100 etc., And other sensor like PS5520, OS08A10, RX2719, GC2093, JXH62, and SP1405 and so on.

If you are planning to develop a project with other sensor, just contact us, we will be your good cooperation partner.

Post time: Mar-28-2023